July 31, 2017

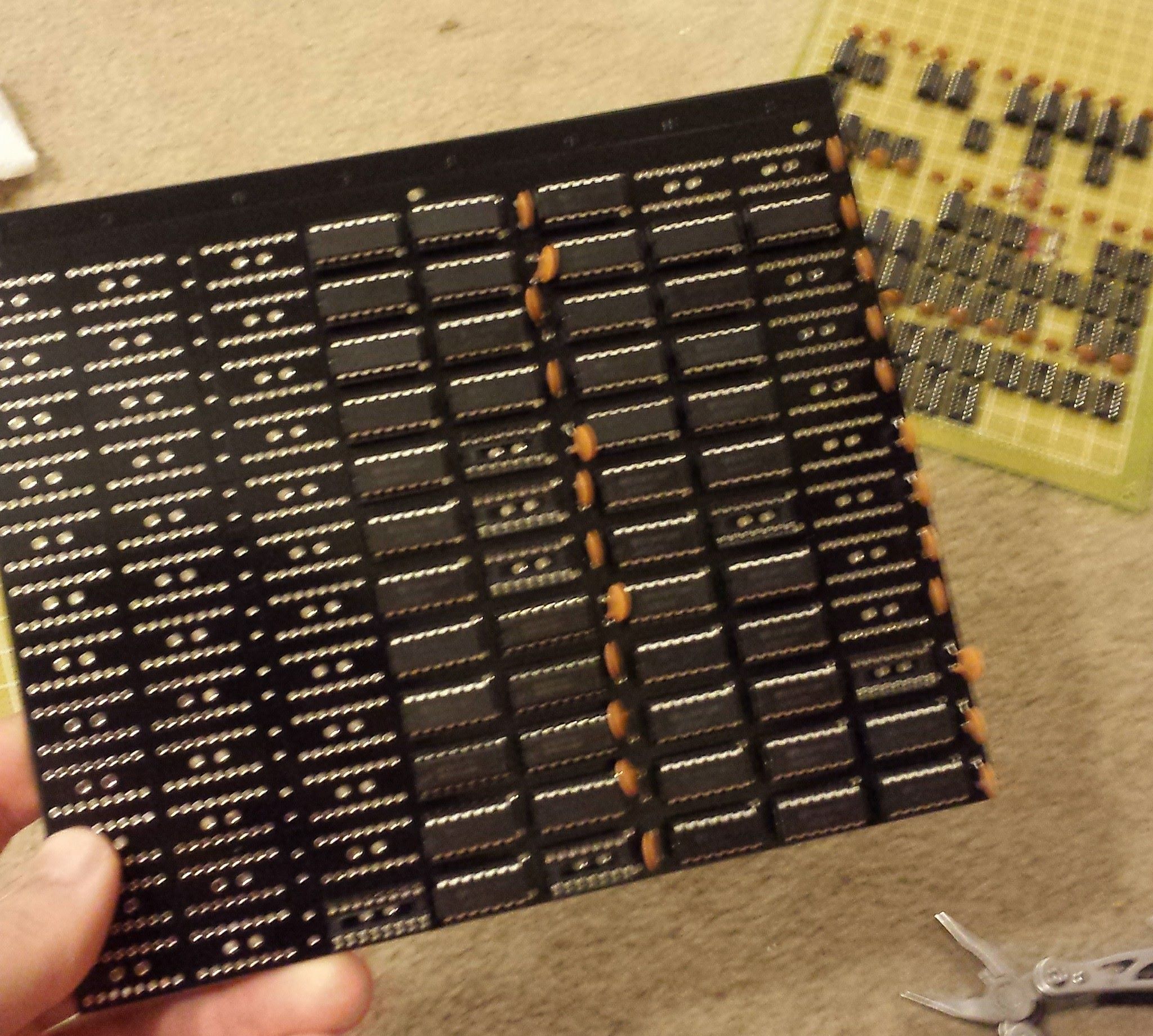

Mouse Droid MSE-6-5C4883R5: Mounting greebiles

Okay, so one last check before putting holes in my shell. It looked to me that one could just find the center point for the side PCBs my rounding the side to a square (like in the top pic). But that doesn’t seem to be the case. Do you mount by aligning the middle fin of the heatsink with the middle of the top greebiles (for horizontal), then make the top and bottom edges of